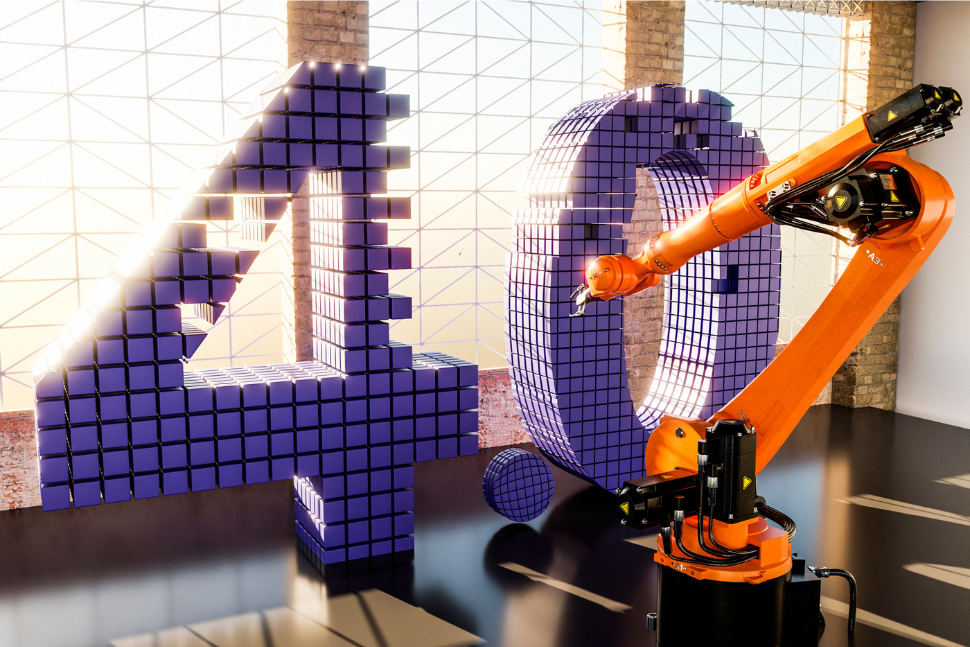

Building on the innovations of the Third Industrial Revolution, Industry 4.0 marks the era of advanced manufacturing technologies. Powered with the strengths of connectivity, automation, and advanced analytics, the Fourth Industrial Revolution is the wave of change global businesses need today.

Today's Manufacturers need to scale up and adapt disruptive technologies like the Internet of Things or IoT, cloud computing, machine learning and AI, and advanced analytics to stay in the game. Businesses also need to focus on delivering more than just products they need to deliver experiences. This is what will set them apart from their competition. So things like customizations, faster turnarounds, and engaging the customer throughout the customer journey are crucial. These new-age technologies not only help them harness the digital age, and help with customer retention but also can prove to be effective in terms of cost and time.

So how can we as manufacturing giants implement changes that align with Industry 4.0 and reap the benefits it has to offer?

Efficiency can be achieved with digital technologies like automation, predictive maintenance, and process improvements implemented in the workplace. An efficient workplace allows quick turnaround times which helps with customer satisfaction. Workplace automation also ensures strict quality control measures which again reduce time and costs.

Creating smart factories with advanced sensors, and robotics are again additions to efficiency. They also allow for better data analysis and more coherent decision-making. Higher value creation is also achieved when production operations are combined with operational data collected from ERP systems, supply chains, and customer service systems. It creates high levels of visibility and acts as feedback for better service.

IoT devices like temperature sensors, pressure sensors, and more in factories help with productivity and accuracy as they help in reducing human error. Small steps like adding AI-powered visual quality checks and inspections help reduce manufacturing errors which eventually save money and time. With small steps like this quality control personnel can set up their devices to the cloud and monitor the manufacturing process from virtually anywhere.

Using machine learning algorithms we as manufacturers can detect errors with a fraction of a second which saves uo on valuable time, raw materials, and money when it comes to operations. These little flaws can be rectified in the earlier stages by using such algorithms. This also shortens the delivery time and helps delight customers.

Such technologies help make working hours more efficient and help you as a brand become sustainable. Small changes like these help reduce factory waste and create efficient and reliable workspaces.

In conclusion, Industry 4.0 is not just a technological shift; it's a transformation that demands the adaptation of cutting-edge tools and a customer-centric mindset. Embracing automation, IoT, AI, and advanced analytics can drive efficiency, quality, and sustainability in manufacturing. These innovations offer businesses the opportunity to streamline processes, reduce errors, and ultimately enhance customer satisfaction. While challenges like cybersecurity and workforce upskilling require attention, the undeniable advantages of Industry 4.0 make it imperative for manufacturers to integrate these changes into their operations if they aim to remain competitive in the ever-evolving market landscape.